ENVIRONMENTAL PERFORMANCE AND INCIDENTS

Performance in FY14

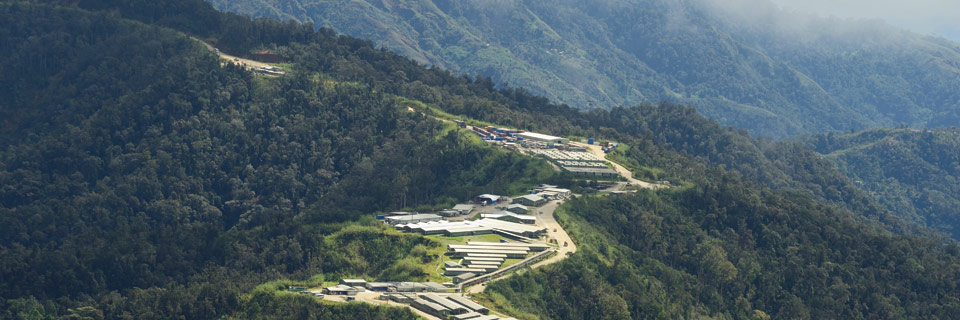

By year end, eight (70%) of our long-life mining operations (accounting for 67% of FY14 production) were ISO 14001 certified, while five (63%) of our processing facilities were certified. Our focus in FY15 will be to achieve certification of the Bambanani and Joel mines in South Africa and of the Hidden Valley operation in Papua New Guinea.

As required by law, all our South African operations have approved environmental management programmes in place, and include outlines for broad closure plans. These environmental management plans have been approved by the Department of Mineral Resources. An amendment to Kusasalethu's environmental management plan, relating to the inclusion of aggregate production from waste rock, was submitted and approved during the year. Amendments to the environmental management programmes for Kalgold, Kusasalethu and two mining rights in the Free State are currently being worked on.

While closure principles are included in their environmental management programmes, detailed closure plans are being developed for Steyn 2 shaft and Unisel. Such plans are developed once operations are within five years of planned closure. At Kalgold, we are re-evaluating our rehabilitation strategy and final land-use proposed for the D–zone pit. We remain in discussion with the departments of mineral resources and of water affairs in reaching an agreed socio-economic solution.

In line with revised legislative requirements, integrated water-use licence applications were submitted to the authorities for each operation in 2006. The integrated water-use licence applications for Kalgold and Kusasalethu have been presented to the licensing committee for consideration and approval, which has been delayed owing to government backlogs.

Implementation and execution of our environmental strategy is directed by an environmental leadership committee at each operation, supported by a group-level environmental manager. General managers retain legal responsibility for our operational environmental performance as well as for compliance with our environmental management plans.

In Papua New Guinea, we seek to reduce our environmental footprint, largely through accelerated rehabilitation. Hidden Valley's environmental management plan is aligned with the ISO 14001 management standard. An important aspect of environmental management in Papua New Guinea is the environmental awareness training provided to all new employees during induction. This is reinforced through leadership training courses and publication of monthly environmental awareness initiatives aimed at the workforce as a whole.

An independent environmental audit of the Hidden Valley operations was undertaken by the joint venture partners in October 2013. A final report was submitted to the Hidden Valley management team in November 2013 and corrective action taken to address concerns identified. These actions were to:

- improve waste management, closure and decommissioning procedures for waste and fuel oil storage areas

- provide a more specific sediment reduction plan to the Department of Environment and Conservation that focuses less on sediment traps and more on source control (for example, better drainage around waste dumps and the stabilisation of exposed slopes)

- provide a specific plan to the Department of Environment and Conservation on how alternative and more site-specific discharge criteria for cobalt and sediment can be developed. These will be included as two additional actions in the environmental improvement plan

- provide training to the sewage treatment plant operators to ensure that consistent treatment dosing procedures are followed, and also that operators are trained on proper sampling procedures

In FY10, the Papua New Guinea Department of Environment and Conservation commissioned a third-party compliance audit of the Hidden Valley mine to address stakeholder concerns about the sedimentation impacts of mining on the Watut River. This compliance audit led to the development and implementation of a Department of Environment and Conservation-approved environmental improvement plan and, in FY11, the appointment of an external stakeholder advisory panel.

By the end of December 2013, 38 of the 40 actions identified in the environmental improvement plan had been addressed to the satisfaction of the Department of Environment and Conservation and local landowners. The deadline for completion of the final two has been extended to December 2014. Work continues on the two remaining actions which had been delayed by a landslide and the unavailability of the necessary construction equipment. Efforts are being made to source the required equipment for which funds have been made available. Good progress was made with upgrades to and automation of the sewerage treatment plants and operator training. This has reduced operator errors and improved overall performance.

The Department of Environment and Conservation met with the Morobe Mining Joint Venture environmental team in May 2014 to discuss outstanding environmental issues and, post year-end, visited, Hidden Valley and Wafi to evaluate overall environmental performance and progress made.

Environmental incidents

Our environmental management plans provide for the monitoring, reporting and remediation of environmental incidents, including direct or indirect discharge of water beyond our mining area.

Our environmental classification system categorises incidents on a scale of 1 to 5. A level 5 incident has mitigation costs in excess of R3 million and a very significant impact on highly valued species, habitat or eco-system, potentially resulting in international condemnation and possible director liability. A level 1 incident represents a low-level non-conformance, where mitigation costs are less than R100 000, where there is limited damage to a minimal area of low impact and where any complaints are localised.

During FY14, there was one level 4 incident (FY13: 0) at Hidden Valley. A total of three level 3 environmental incidents were reported, all at Kusasalethu. A level 3 incident results in mitigation costs of between R250 000 and R500 000, has serious medium-term environmental effects and may result in serious adverse media attention. No environmental directives were received from the authorities as control and mitigation of the incidents were adequate.

ENVIRONMENTAL INCIDENTS (LEVEL 3 AND 4) IN FY14

| Date | Operation | Cause |

|---|---|---|

| 11 December 2013 | Kusasalethu (level 3) | Following a heavy rainfall, the return water dam overflowed. Although the impact was limited as a result of dilution, the permit conditions were breached. The incident was reported to the Department of Water Affairs and a comprehensive action plan to prevent similar incidents occurring was submitted for approval by 30 January 2014. This plan was subsequently implemented. |

| 10 March 2014 | Kusasalethu (level 3) | A third-party company operating a waste water treatment works adjacent to Harmony's pollution control dam inadvertently discharged raw sewage into the dam resulting in the death of fish. There was no impact on downstream dam users as the incident was swiftly localised and contained. The incident was reported to the Department of Water Affairs and the regulators during their site visit. A section 55 instruction was issued by the Department of Water Affairs, instructing Harmony to improve access control measures. Fencing is to be installed to ensure that community members have no access to the treatment works as these are located within the operational mining area. |

| 19 June 2014 | Kusasalethu (level 3) | The motor on the vertical spindle pump returning water emanating from the main surface fans, failed, resulting in water overflowing at the pump sump into the storm water system. Approximately 2.8l/s (0.24Ml/day) flowed into the storm water stream for a period of 72 hours. Given the results of the basic tests conducted on 25 June 2014, the preliminary impact on the water resources was deemed to be low. |

| 11 June 2014 | Hidden Valley (level 4) | This incident involved the sewage treatment plant at the Ridgeline Camp site. Sewerage sludge from the digester was discharged into two underground septic tanks to reduce build-up in the digester. These septic tanks overflowed resulting in approximately 20 000-25 000 litres of sewerage being discharged from the overflow pipe directly into the environment. Affected areas were inspected to ensure no further overflow. Action was taken immediately to check the area for contamination and to implement clean up and containment procedures if required. A report has been submitted to the Department of Environment and Conservation as required in terms of our permit. |